MY MENTAL PICTURE of a traditional holiday scene includes a well-ornamented tree, stockings hung with a reasonable amount of care, and a small train set chugging enthusiastically around the living room. I never had an HO set as a kid, but recently made up for that lack by plunging into the world of model railroads. And wouldn't you know it? There's an extra feature that didn’t exist during my childhood: you can run your locomotives through your computer.

MY MENTAL PICTURE of a traditional holiday scene includes a well-ornamented tree, stockings hung with a reasonable amount of care, and a small train set chugging enthusiastically around the living room. I never had an HO set as a kid, but recently made up for that lack by plunging into the world of model railroads. And wouldn't you know it? There's an extra feature that didn’t exist during my childhood: you can run your locomotives through your computer.Not literally, of course, unless you point the track the wrong way. The computer acts as a throttle for feature-enhanced locos (to use the hobbyist’s jargon), letting you control several of them separately on a given layout. Digital command control (DCC) makes sense: it’s used with for-real trains, so why not with hobbyist models, too? Thanks to standardization implemented by the National Model Railroad Association (NMRA), digital control can be built into locomotives and add-on hardware with reliable compatibility.

You can find computer programs that help you design track layout or simulate conditions in the locomotive – look for a demo version of Atlas’s RightTrack software on Computer Life’s forums on America Online, ZiffNet, and the Microsoft Network – but this project gives you onscreen control, to the point of regulating acceleration speed and telling the train how long it should sit at a station.

The same technology that’s shrinking your desktop computer is making DCC possible. Now there are microprocessors small enough to fit into a model train – and there’s not much room in an accurately reproduced locomotive that’s going to have power enough to tug a bunch of cars around the track.

Electrical communication with a locomotive is limited by the transmission medium – everything has to pass from the rails of the track to the wheels of the train. But that’s the same limitation that modems have managed to flourish in spite of; digital train control sends its own set of serial information packets back and forth.

Anything that’s affected by electricity, then, can be computer controlled. Which locomotives to run, how fast they should go, which switches should switch, even when to light up and drop a crossing gate. Even better, you can combine much of this activity in a timetable that lets you automate as much of this as you’d like.

Which is great for the kind of operating sessions the better railroad clubs like to run. That’s where you find members working a walkaround layout by taking on the various roles needed for smooth operation. Someone will dispatch the trains; someone else will set up and couple cars. Rail engineers control the speed, switchers change the direction. With a fully (or even partially) implemented computer-based system, you can follow the progress of your trains on screen even as you guide them around the table.

If you’re starting from scratch, as I did, you can immediately set up your engines for computer control. If you or your club is already running a massive setup, you can gradually introduce this technology. It’s cutting edge stuff in the model train world, where stodgy old rivet counters, who don’t want anything to change, are giving way to new generations of open-minded hobbyists.

You need both train-control software and a hardware interface to plug between your power pack and the track rails. For the hardware, I used Digitrax’s LocoNet system, which lets you wire a series of command stations around your layout. Using a serial interface, WinLok software takes over throttle and switch control. And it goes way beyond that. A sophisticated programming language lets you develop intricate combinations of events, all of which can be combined into and save as a timetable. If you prefer the thrill of direct interaction, there’s a layout design module that lets you depict and even operate the switches and other digital gadgets on your track.

To start, of course, you need a train. I spread a simple oval layout on the dining room table and set to the task of assembling a small fleet of HO-scale cars, marvelling at the detail of each component. I quickly learned that a section of track called a re-railer is vital to a thick-thumbed fumbler like me, who has trouble aligning the flanges on those little wheels to properly hug the track. (With the even smaller N scale of model trains, I suspect I’d be a total loss.) The fleet began with a small assortment of cars and a beautiful Atlas reproduction of a U36C locomotive painted in the familiar blue Conrail style.

My wife, who developed an unexpected fascination with this project, helped put together the cars and glued together a hundred-piece scale model of a station house we got to add a little scenic verisimilitude to our layout. But one train on the track gets to be a one-note melody. You want more locos, more switches, more challenge. That’s where the computer eases the effort. In the old days, you had to buy a separate power pack for each engine and wire individual sections of track to isolate them. A DCC rig puts it all on the same track system, giving you the risks and challenges of real-world switching.

NMRA standards also cover the specifics of putting a DCC interface into a locomotive. A tiny eight-socket jack gets tweezed onto a circuit board under the engine’s cover, with room enough to plug in and secure the computer chip-sized decoder. If you already have locos that lack the jack and you’re comfortable with a soldering iron, you can still get a decoder in there. You need to interrupt the circuits that send power from the wheels to the motor brushes, and make sure that the forward and reverse lamps on the engine also get properly connected. I managed a conversion in less than half an hour.

By default, the decoders are programmed to run on channel 3, which is what we’ll use for the single locomotive in this project. But the Digitrax system gives you a total of 235 other channels, so don’t worry about running out of addresses, and decoders are easy to reprogram.

My next project is to put a decoder on my switches and program it into a WinLok switchboard. My wife wants to get a crossing gate that an approaching train will activate. And don’t forget that trains are supposed to be a multimedia experience: Digitrax is working on a system that will let you hide speakers around your layout to enjoy the appropriate sounds as locomotives speed through your miniaturized villages.

In other words, beware the obsessional nature of this hobby. There’s no sense of power more complete than the one I’m feeling as I send the Computer Life Express roaring through my dining room, but don’t you think another boxcar and a reefer would improve its appearance?

Step 1: Install the DB100 booster.

Make sure your power pack is unplugged, then disconnect the DC output wires from their trackside screw terminals. Push them into the terminals on the DB100 marked Power In. Strip the ends of a short length of wire and push one end into the terminal marked Sync, the other into the terminal marked Ground. Strip the ends of a length of twin-lead wire, and push one set of ends into the DB100 terminals marked Rail A and Rail B. Fasten the other ends to the screw terminals of your track.

TIP: If you’re handy with a soldering iron, make all these connections easier for yourself by coating the stripped ends of the wires with solder. It’s called "tinning the leads," and it keeps those tiny wire strands from scrunching around the edges of the connection terminals.

ANOTHER TIP: I keep a stick of wax on hand when working with tiny screws. Dip the screwdriver blade into the wax and it will then hold on to the screw long enough to get it started in the hole--and you don’t have to magnetize anything.

Step 2: Connect the LocoNet adapter.

It’s an odd-shaped gadget the size of a pack of chewing gum, with a modular plug input at each end. One end also has three wires sticking out. Push the ends of the two smaller wires--one is orange, the other gray--into the DB100 terminals marked Rail A and Rail B, piggybacking them with the track connections. The larger wire is a flat phone lead with a six-conductor modular plug at the end. Push it into either of the DB100's two LocoNet jacks.

It’s an odd-shaped gadget the size of a pack of chewing gum, with a modular plug input at each end. One end also has three wires sticking out. Push the ends of the two smaller wires--one is orange, the other gray--into the DB100 terminals marked Rail A and Rail B, piggybacking them with the track connections. The larger wire is a flat phone lead with a six-conductor modular plug at the end. Push it into either of the DB100's two LocoNet jacks.Step 3: Connect the DT200 command station.

Pop open the back of the DT200 controller and install a 9-volt battery. The connectors aren’t polarized, so make sure you align the battery correctly (+ to +). Close the back. The controller will beep and its LCD display will read Idle. Push and hold the Run/Stop button on the face of the DT200, and push and hold the button immediately below it (which has a two-headed arrow as its icon). After a couple of seconds the controller will beep again and change the display to read SE:L. At the end of the DT200's phone lead is a modular plug; plug it into the LocoNet adapter jack marked A.

Step 4: Connect the LocoNet adapter to your computer.

You need to supply a length of six-strand phone wire with a six-conductor modular plug at each end. You can buy it assembled at Radio Shack or a good telephone supply store. Plug one end into the LocoNet adapter, opposite jack A, and plug the other into the Digitrax serial port adapter. Make the computer connection by plugging the adapter into a free serial port.

Step 5: Install the DH84P decoder into a locomotive.

Remove the top of your DCC-compliant locomotive. I used an Atlas U36C, which has the proper connector and room enough to stash the decoder. Remove the dummy plug by rocking it gently from the socket, and replace it with the plug at the end of the DH84P, making sure the red wire is on the engineer’s (right) side of the loco. Loop the wire so that the decoder lies on top of the printed circuit board, and replace the top of the locomotive.

Remove the top of your DCC-compliant locomotive. I used an Atlas U36C, which has the proper connector and room enough to stash the decoder. Remove the dummy plug by rocking it gently from the socket, and replace it with the plug at the end of the DH84P, making sure the red wire is on the engineer’s (right) side of the loco. Loop the wire so that the decoder lies on top of the printed circuit board, and replace the top of the locomotive.Step 6: Install the WinLok software.

Place the WinLok installation disk into drive A:. If you’re running Windows 95, open the Control Panel folder, choose Add/Remove Programs, and click Install. Click Next at the next window; with A:\INSTALL.EXE highlighted in the following window, click Finish. Windows 3.1 users can pull down the File menu, click Run, and type A:\INSTALL in the dialog window. Confirm C:\WINLOK as the destination directory, and let the installation program do the rest. Start the program. Install the Digitrax driver by pulling down the General menu, choosing General Setup, and selecting DIGITRAX.DRV from the Drivers list. I completed my setup by pulling down the newly-added Digitrax menu, selecting Serial Interface, and choosing COM 1.

Place the WinLok installation disk into drive A:. If you’re running Windows 95, open the Control Panel folder, choose Add/Remove Programs, and click Install. Click Next at the next window; with A:\INSTALL.EXE highlighted in the following window, click Finish. Windows 3.1 users can pull down the File menu, click Run, and type A:\INSTALL in the dialog window. Confirm C:\WINLOK as the destination directory, and let the installation program do the rest. Start the program. Install the Digitrax driver by pulling down the General menu, choosing General Setup, and selecting DIGITRAX.DRV from the Drivers list. I completed my setup by pulling down the newly-added Digitrax menu, selecting Serial Interface, and choosing COM 1.Step 7: Describe your locomotive.

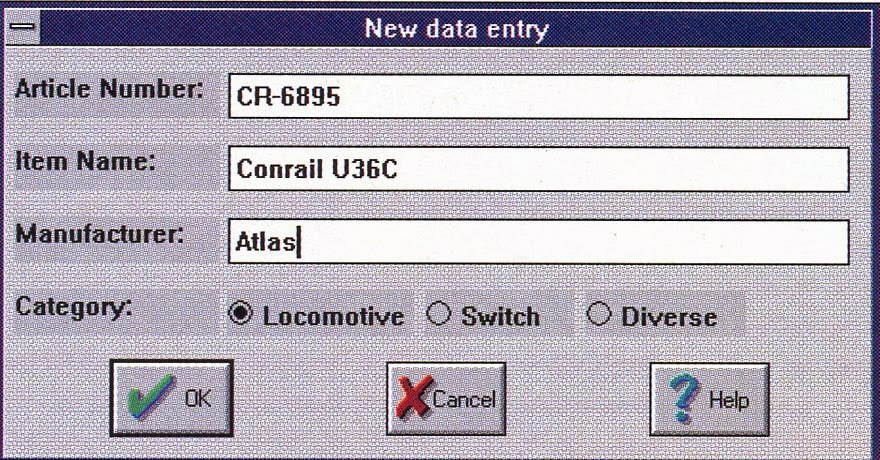

Pull down the Database menu and select Items. This is where you enter information about anything – locomotive, switch, whatever – that’s computer controllable. Click the New button. Article Number, the first entry, is for your own reference; I typed CR-6895, combining the Conrail reporting mark (CR) and the road number of the locomotive I worked with. Press the Tab key to go to the Item name box, where I typed Conrail U36C. Manufacturer is Atlas, and in the Category section the Locomotive button should be selected by default. If not, select it. Click in the upper left corner to close the window.

Step 8: Add your locomotive to the database.

At the main window, pull down the Database menu and select Locomotives. Click the New button. Type 3 in the Digital-Nr. box, which is the default channel for the decoder. Pull down the Item-Nr. list and select CR-6895, which also fills in the Item Name box for you. Location is next: in my case, it’s Byron’s Yard--type in whatever you name your layout. Filling in the rest of the dialog is easy. Click Use Default for the Speed Function settings; for Time Delay Functions, type an exclamation point (!) for the Acceleration and Deceleration settings. Click OK to finish.

Step 9: Set up a throttle for your locomotive.

Pull down the Loco Controller menu and select New. You’ll see a small box with a slide control in the center. Click the small red box marked S (for Setup); down the box at the top left of the next dialog (Select Locomotive). Choose Conrail U36C from the selections and click OK. At the main screen, pull down the General menu and select Go. When you click and drag the slider bar on the throttle window, your locomotive will start to chug down the track.

Step 10: Add another locomotive.

One locomotive on a computer throttle? Hardly a challenge. The beauty of the Digitrax/WinLok combo is that you can run several locomotives as well as your switches through the computer. Even a non-DCC locomotive can be adapted to decoder use, which I did successfully with patience and my trusty soldering iron. Program the decoder to a different channel, enter the information in WinLok’s database, and add it to your throttle control. You’re just getting started on a railroading adventure that brings an exciting new face to a popular old hobby.

– Computer Life, December 1995

No comments:

Post a Comment